Motorcycle Parts New Zealand Specialists Things To Know Before You Buy

Table of ContentsUnknown Facts About Motorcycle Parts New Zealand SpecialistsTop Guidelines Of Motorcycle Parts New Zealand SpecialistsThe Of Motorcycle Parts New Zealand SpecialistsEverything about Motorcycle Parts New Zealand SpecialistsThe Of Motorcycle Parts New Zealand SpecialistsMotorcycle Parts New Zealand Specialists Can Be Fun For AnyoneMotorcycle Parts New Zealand Specialists Things To Know Before You Get ThisMotorcycle Parts New Zealand Specialists Fundamentals Explained

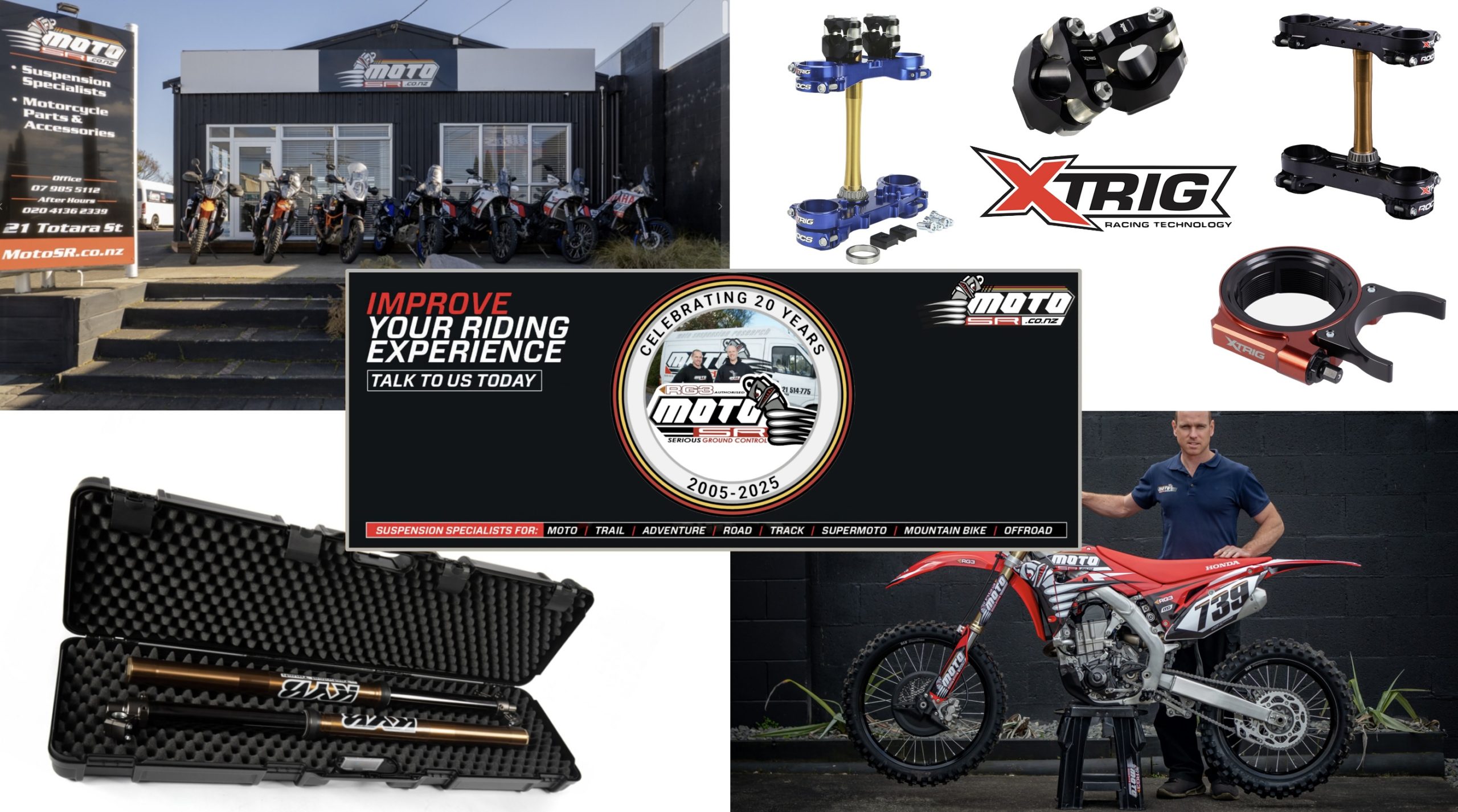

So, connect to one of our specialists today.CNC machining modern technology is quickly becoming the centerpiece of several manufacturing processes around the world as a straight result of its many advantages over various other techniques. Furthermore, the markets that produce motorcycles have actually gotten on board with this trend. One of the most innovative business are currently developing their engine parts and wheels making use of machining methods originally created for motorcycle components.

You may be asking yourself why we utilize. Currently that we have your focus let us explain the reasoning behind this modern-day development in the motorcycle production market.

The 9-Minute Rule for Motorcycle Parts New Zealand Specialists

Additionally, you have complete control over the look of the parts, also to the min information. Sometimes, motorcyclists might determine to fix up their ride by setting up aftermarket components or customizing the bike's remodeling. Once once again, computer mathematical control (CNC) machining is the most functional technique. Upgrades may be of any type of kind and design you desire.

Not known Details About Motorcycle Parts New Zealand Specialists

CNC machining may be made use of to make almost all of a motorbike's metal and plastic components. To continue, we'll discuss numerous machined components for bikes.

When tailoring the wheels, the disks are where the focus should be. The majority of them are made out of light weight aluminum. Aluminum alloys are widely known for the outstanding machining capacities that they have. Milling treatments are used to obtain the desired level of wheel customization. An additional element of the motorcycle that may be personalized is the tires.

The Best Guide To Motorcycle Parts New Zealand Specialists

When it comes to a lorry (or a motorbike), one of the most important component is the engine. Several individuals point to it as the "heart" of the automobile. On the various other hand, the camshaft, the cylinder head, and the pistons tend to be elaborate and need layouts with a high degree of accuracy.

Illumination is another complicated element of personalization. Usage only top notch items, nonetheless, since these lights are crucial for the safety and security of motorcyclists and other motorists or individuals when traveling, particularly at evening. Motorcycle headlights have 3 almosts all: the light bulb, or light resource, the lens, and the housing. Particularly, we tailor the lens and the housing.

Milling procedures with a flawless coating would certainly result in the lenses having a reflective quality that resembles that of a mirror. The cover, on the other hand, is not composed of delicate materials; instead, it is constructed out of hard polymers that can be machined into more detailed patterns.

Motorcycle Parts New Zealand Specialists Fundamentals Explained

Motorcycle suppliers typically cast these elements, however just for the manufacturing of bespoke parts. Machining on five axes in today's world is the ways by which any style shape may be recognized.

Choose Runsom for your personalized motorbike components! We have the capacity to fabricate complex and elegant components making your motorbike unparalleled.

Below are a few examples of metals usually utilized in motorbike part machining. Aluminum is the primary material utilized by business concentrating on generating personalized motorcycle elements to develop the majority of these parts. In the past, we would certainly construct our engines out of actors iron. On the various other hand, aluminum is swiftly coming to be the product of choice, partly due to the reality that it is much more light-weight.

Zinc describes an additional steel that is extremely light in weight and has great machining qualities due to its high mechanical strength. my sources This product might be formed right into nearly any type of shape and maintains its dimensions well. Even mission-critical elements that need a high degree of precision may profit from their use.

Some Of Motorcycle Parts New Zealand Specialists

Another metal that sees heavy use in the manufacturing of CNC-customized special info components is magnesium. It is amongst the lightest steels that are now obtainable and has outstanding machinability functions and strength compatible with its low weight. One of the disadvantages of magnesium is that its dirt may quickly capture fire.

Due to its exceptional machinability and weldability, stainless-steel is an alloy that is especially well-suited for CNC procedures. Along with this, they have fantastic rust resistance and a high visual pop over to this web-site allure. Their most usual use in generating various motorcycle parts is fasteners, such as screws and screws. Their low susceptibility to oxidation and rust makes them perfect for this usage.

Examine This Report about Motorcycle Parts New Zealand Specialists

It appears that CNC transforming and milling are the foundational processes. In enhancement, it requires keeping bars of product, most commonly plastic or metal, in placement and then turning a reducing device to get rid of sections of the product as the material is transformed.

These approaches are just as vital and produce parts with high accuracy and regular top quality. The processes help enhance the overall high quality of the machined bike elements.

See This Report about Motorcycle Parts New Zealand Specialists